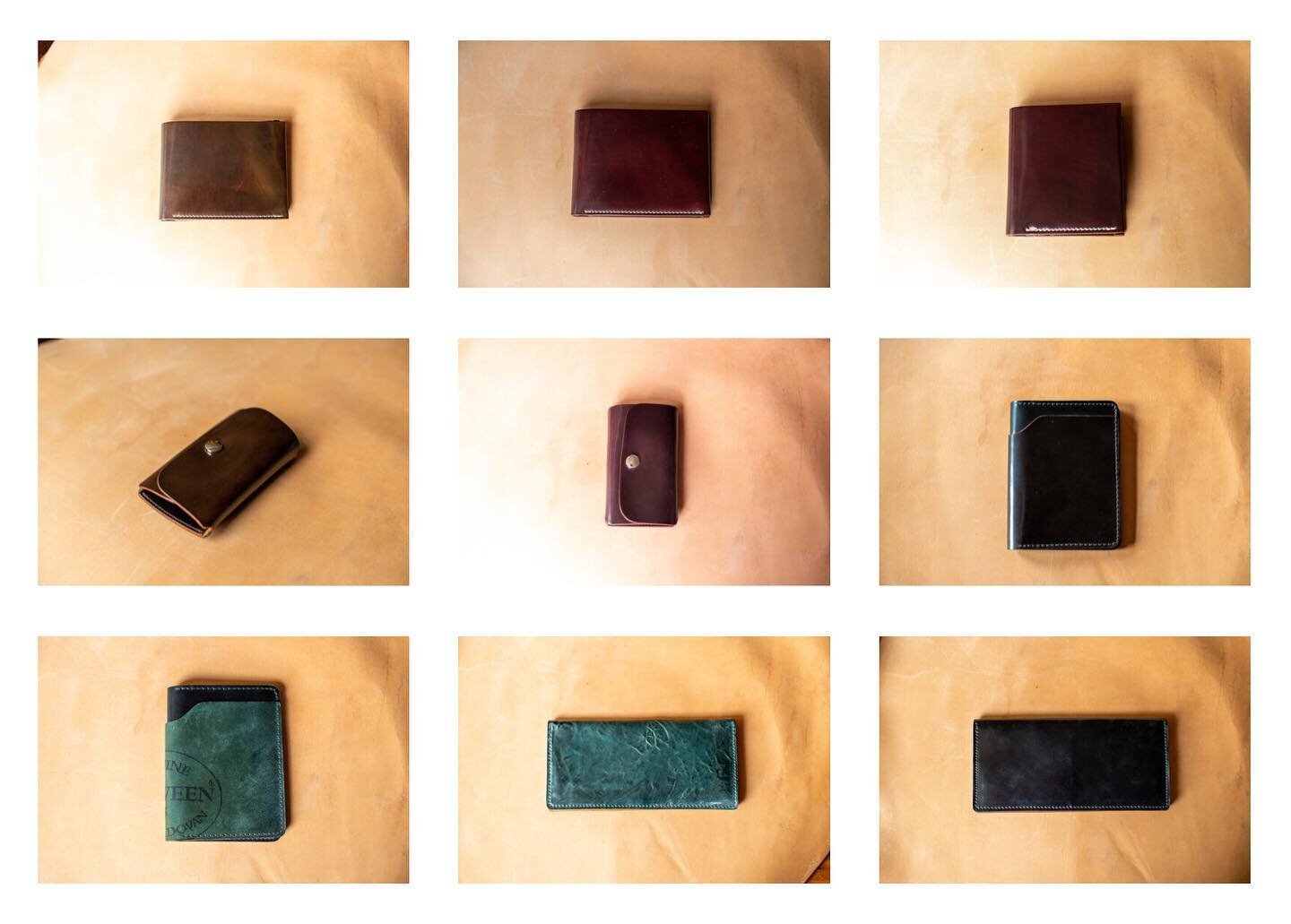

Making the best means doing a lot of little things right. To ensure top quality finished goods, we start with top quality components. That means using native hides for the best grain and yields, premium grade oils, dyes, and retanning agents. Our formulas cut no corners, and we are one of only a handful of tanneries in the United States that still processes hides from their raw, cured state to finished leather.

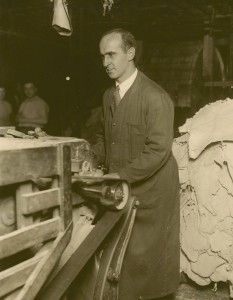

The Horween Name

"We should take the best of everything; the best hides, the best oils, the best dyes and finishes – then we do whatever it takes to make that leather the best. The price goes on last, and if we cannot sell it for what it is worth, we should not make that leather."

- Isidore Horween, Master Tanner and Founder, 1905 - 1948

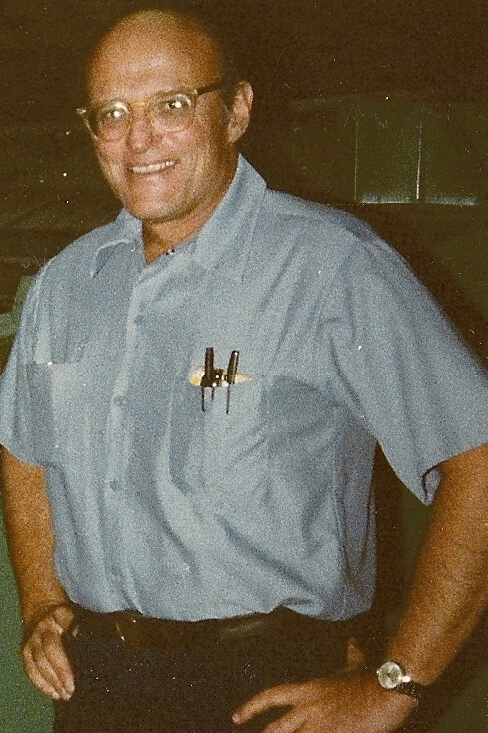

“We always felt there was a right way and a wrong way to make fine leather. It takes us at least six months to make a cordovan shell. Our cordovan could probably be made faster, and people might not even be able to tell the difference… but I can.”

- Arnold Horween, Sr., President 1949- 1983

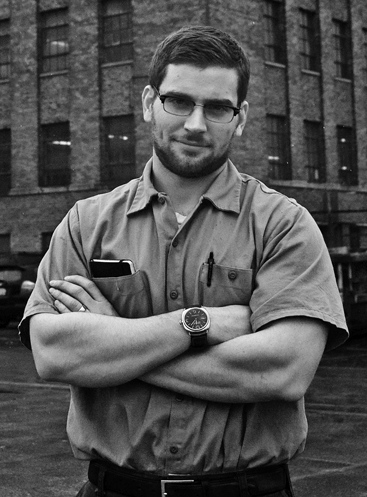

“As tanneries go we’re not the biggest, the fastest, or the cheapest, which means we need to be the best. Our business is built on doing things other people don’t, won’t, or can’t.”

- Arnold Horween, Jr., President 1983 - 2003

“Quality must be more than a word. It doesn’t belong to one company or one country, it doesn’t happen by chance, and it requires constant attention. It’s a contract between seller and buyer – an agreement that something is good and worth having. Our greatest enemy is the phrase ‘it’s good enough’.”

- Arnold "Skip" Horween III, President 2003 - present

Contact Us

2015 North Elston Avenue || Chicago, IL 60614 || Tel. (773) 772 2026 || Fax (773) 772 9235